What is tangential shrinkage in wood? | Everything you need to know before choosing your timber

Being a product of nature, and filled with moisture, wood responds to its surrounding environment in sometimes erratic and unpredictable ways.

And no matter how wood has been treated, it will continue to move, expand, shrink, and warp over time. Luckily, it is possible to anticipate wood’s sometimes mysterious behaviour – and build accordingly.

In this blog, we look at what is tangential shrinkage in wood, why it matters and how to build with this natural and unavoidable phenomenon in mind.

So what is tangential shrinkage in wood?

Tangential shrinkage occurs when wood shifts along its growth lines. This process is one of several that occur once the wood has been chopped from its original tree. Tangential shrinkage is known to be the most active process and holds great importance for anyone hoping to build with wood. Before we go into detail, let’s take a look at longitudinal and radial shrinkage:

Longitudinal shrinkage

Longitudinal shrinkage occurs when wood shifts upwards and downwards (lengthwise). Compared to the side-to-side movement of tangential shrinkage, longitudinal shrinkage occurs the least (between 0.1 and 0.2%). Broadly speaking, these numbers are inconsequential for most building projects.

Radial shrinkage

Radial shrinkage occurs when wood shifts inwards and outwards in relation to the original tree trunk. Radial direction shrinkage, therefore, occurs at right angles or perpendicular to the growth rings. Typically, Radial shrinkage will have half the average shrinkage values compared to tangential shrinkage.

Volumetric shrinkage

Together, these natural movement processes are known as the wood’s volumetric shrinkage. Of the three, tangential shrinkage results in the most movement in the wood and is of the most importance when it comes to building projects where for example timber ceilings are a key component in the structure.

Why does tangential shrinkage occur?

Tangential shrinkage is driven by changing moisture content in wood. When trees are alive, they suck up moisture from their roots and distribute nutrients via their trunks and branches – helping them grow. Water is stored either as free water or as cells (part of the cell walls).

When wood is cut from a tree, its moisture levels are no longer dependent on the roots and vessels of the tree, and it starts to shed the free water until the fibre saturation point is reached. This typically leaves the wood with moisture content levels between 25% and 30%. Over time, moisture loss from the cell walls on the tangential side will start to cause the wood to shrink.

Why tangential shrinkage matters

Even with heavy treatment, different species of wood will continue to move and shift depending on the environment. Only when wood reaches equilibrium moisture content (EMC) will it be in balance with the surrounding atmosphere and humidity.

Measuring and anticipating shrinkage levels is important for builders and designers who plan on using timber for larger projects. A 7% change in shrinkage could be the difference between a successful project and a complete design debacle.

Even smaller 3 or 4% tangential shrinkage levels can have a large impact on some projects where the sides of the wood panels are adjoining exactly where shrinkage occurs.

How to account for tangential shrinkage in your project

Anticipating tangential shrinkage levels and wood movement should start during the design phase of your project. If you have a specific type of timber in mind for a feature wall, architectural cladding or similar, you’ll want to make sure you understand the near-term and long-term levels of shrinkage before putting your order down and cutting lengths or panels. Remember, the larger the panels are – the more shrinkage you can expect.

It’s important to mention that no one can 100% predict the exact levels of shrinkage – as it never occurs in a linear or completely predictable way. We recommend checking with your supplier to see what moisture content the timber has and what the seasoned shrinkage will be. Don’t forget to factor in any major local environmental changes that might affect your timber over time.

Tips for working with tangential shrinkage

There are several ways builders and architects can overcome varying shrinkage levels. Here are some:

- Choose wood species with low levels of shrinkage

- Where possible, opt for radial-cut or quarter-sawn wood over tangential (back-sawn) wood

- Design with the wood’s moisture content and potential shrinkage in mind. This is especially important if you expect your timber to move a lot over time

- Apply finishes equally and on both sides to reduce distortion and unintended dimensional shrinkage

Tangential shrinkage and wood types

All trees have different amounts of moisture content, depending on their surrounding environment, and of course the wood species themselves. In the same way, each wood product or piece of fresh lumber will have its own levels of moisture which will slowly reduce over time. Here are some examples of timber sold right here at Mortlock Timber with varying tangential shrinkage levels:

- Victoria Ash 8.5%

- Jarrah 7.4%

- Vacoa 3.0%

- Pacific Teak 2.0%

- Burnt Ash 0.5%

- American Oak 6.6%

- Blackbutt 7.3%

- Ironbark 6.3%

- Spotted Gum 6.1%

Source quality timber with Mortlock Timber

Sourcing quality timber with accurate shrinkage values can be difficult, especially if you’re looking at buying second-hand or from a local or uncertified supplier.

When you order your timber with Mortlock Timber you can have peace of mind knowing that we treat all timber to the highest standards meaning you can move ahead on your project with confidence. For sustainable, quality timber, contact Mortlock Timber today.

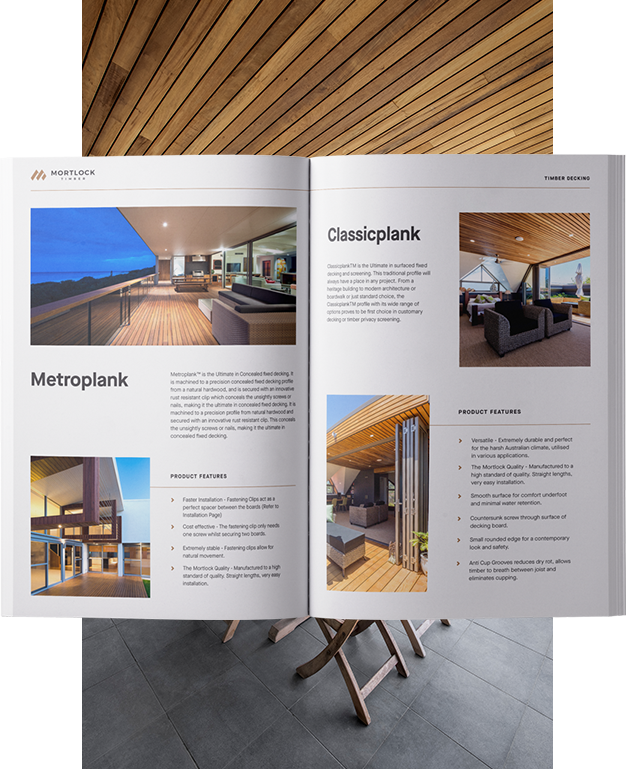

View our pricing and product guide

We are committed to bringing you timber products that add value and endure for years to come, even in heavy traffic and harsh weather conditions. We understand the value of efficiency when it comes to installation and keeping hardwood timber costs down. That’s why we’ve spent decades perfecting our designs to make them easier to handle, less wasteful and more efficient to install. This efficiency allows us to offer you premier products that are more cost-effective so that you can experience greater savings on timber wall costs, timber ceiling costs, timber cladding costs and timber decking costs.

Download our Pricing and Product Guide for our complete hardwood timber price list including timber decking prices, timber wall prices, timber ceiling prices and timber cladding prices.