The Ultimate Guide to Thermally Modified Timber

In design, there are many challenges to using sustainable and natural materials. In the realm of architectural timber, innovation often leads to combating concerns and problem solving.

Such an innovation that we at Mortlock Timber celebrate and take advantage of is thermally modified timber. This transformative process offers not only performance, but incredible aesthetics that allow for architectural timber to be featured in designs across the world in many a different climate.

In this blog post, we delve into the intricacies of thermally modified timber, exploring its process, benefits, applications, and the range of species and finishes available at Mortlock Timber.

Let’s talk about thermally modified timber, its performance, advantages, applications, the range of species we offer and the finishes we use on thermally-modified timber.

Here is what we will cover in this guide:

- What thermal modification is

- The advantages of thermally modified timber

- The different types of thermally modified timber

- The application and best uses of thermally modified timber

- The performance of thermally modified timber in Australia

- Thermal modification finishes and maintenance

What is thermal modification?

Thermal modification is a chemical free and pressurised process that involves high heat steaming. This isn’t a composite product; this is real timber that has changed at a cellular level to provide upwards of 30 years of life expectancy.

The fundamental feature of thermal modification is to change the timber’s relationship with moisture. Making the timber essentially ‘hydrophobic’.

Treating the wood at a very high temperature, creates a natural chemical reaction between the lignins, cellulose and the hemicelluloses in the timber. This means that the sugars in the timber are baked out, removing some of the wood’s organic compounds.

These transformative, structural and visual changes from the process, lead to extraordinary advantages when incorporating architectural timber into a design.

What is thermally-modified timber?

Thermally modified timber is wood that has been heated in temperatures greater than 190 degrees Celsius to create changes in the wood at a cellular level. These structural and cellulose changes improve the timber’s durability, stability and resistance to rot and termites.

The advantages of thermally modified timber

Formation, resilience and stability

The timber is less prone to warping, cupping and thermal expansion when it comes to temperature, humidity and water. The structural changes that occur during the thermal modification process are a result of the expulsion of moisture from the timber.

Little to no moisture in the timber means that there is no water available to cause swelling, shrinking or warping of the timber that is exposed to the weather – that is ever-changing.

By maintaining its shape and integrity, thermally modified timbers provides fewer entry points for moisture and other microorganisms to enter.

Resistance in rot, decay and insects

As moisture is expelled during the thermal modification process, the timber is less hospitable to fungi, mould and bacteria. With insufficient moisture, the conditions for rot to fester and decay to appear.

Resistance in rot and decay as the process has removed the organic properties that cause the timber to rot and ultimately stops the need to replace decaying timber.

These changes within the timber make it less digestible and less appealing to wood-destroying organisms like fungi and insects.

When it comes repelling insects and termites, thermally modified timber is an attractive option for external applications and will often be the best option if this is a primary concern. However, there is not enough evidence of thermally modified timber completely repelling insects and termites.

If the timber is treated and coated, the barrier created from certain finishes contain preservatives repelling insects and prohibiting them to access the timber fibres.

At Mortlock Timber we pre-finish all our timber products with coatings such as Cutek Extreme CD50 oil, that penetrate and protect the timber it is applied to.

Aesthetics

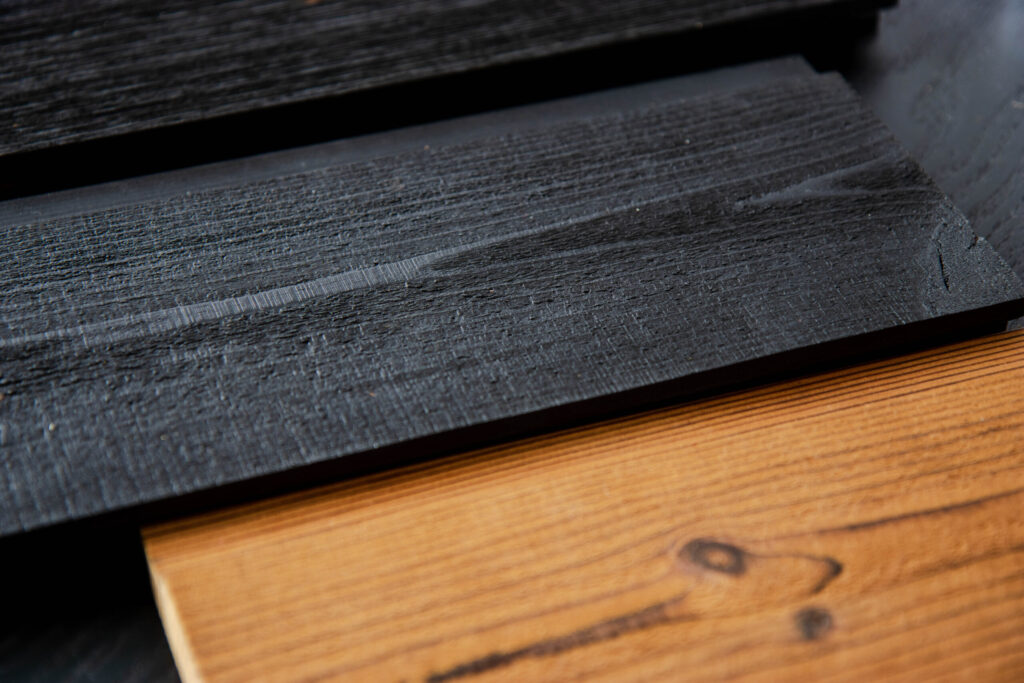

Thermally modified timber has distinct characteristics and colour that result from the thermal modification process. The change of colour, texture and grain are the most noticeable on the piece of timber once it been removed from the specialised kilns.

For example, American ash generally has a pale to white sapwood complexion, with a heartwood that ranges from greyish brown to light brown. Once treated with thermal modification, ash’s timber colour transforms into a rich brown with deep notes.

Consistent weathering of the timber

As thermally-modified has gone through a process removing these lignins from the woods, providing an opportunity for the timber to weather off to the natural elements in an even, consistent manner. This results in the breakdown of lignin and the bleaching of the wood’s surface, leading to a loss of color and the development of a greyish patina.

What thermally modified timber do we offer at Mortlock timber

Tulipwood

Thanks to the process of thermal modification, Tulipwood goes through a captivating transformation that yields a luscious palette reminiscent of dark chocolate tones. This natural process not only imparts a silky-smooth texture but also accentuates the distinctive grain patterns within each panel.

The result is a spectrum of rich brown hues ranging from amber to dark brown, mirroring the allure of exotic woods of North America.

Malvec

Malvec is thermally-modified product here at Mortlock Timber. It is typically known as Ayous, a tropical tree that is native to West and Central Africa. Ayous is an exotic timber that has a bright, creamy white to yellow look.

Malvec undergoes that transformative process that reveals enhanced characteristics. This includes a visually appealing shift to dark, luxurious browns.

Firstly, it offers a more economical option compared to cedar while boasting superior durability. Western red cedar may develop certain dark and uneven discolouration when externally installed and designed to weather off.

Malvec as a thermally modified timber will avoid certain problems on externally installed surfaces that are designed to weather off. Additionally, Malvec presents a more cost-effective solution than cedar, making it an attractive choice for those seeking both quality and affordability in their timber products.

Burnt Ash

Burnt ash is thermally modified American ash, a strong and resilient hardwood timber grown predominantly in North America. The chemical-free thermal modification process uses heat and steam to improve the durability and rot resistance of the timber. Essentially, cooking the timber.

Burnt ash is one of the best timbers for Shou Sugi Ban, due to its high stability and relatively low density. Compared to Australian hardwood timbers, burnt ash can achieve a deeper char layer, reducing maintenance requirements and improving the durability of the timber.

Vacoa

Vacoa is a sustainable Nordic knotty pine material that comes from thermally treating Nordic Pine. It’s produced in Europe and the thermal process drastically increases the stability of the timber. This makes Vacoa easy to work with and can therefore be used for both interior and exterior applications.

Where can you use thermally modified timber?

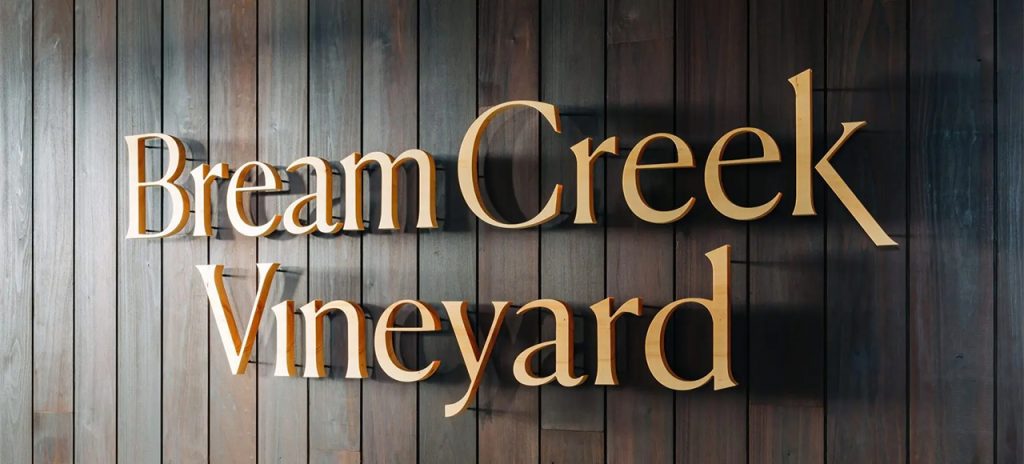

External

Because of the durable nature of thermally modified timber means it is less susceptible to environmental factors that commonly degrade timber over time. With little to no warping, cupping and flaking, this timber maintains its shape and appearance over the long term.

Internal

The main draw for using thermally modified timber internally is the aesthetically appealing colours and texture found on the timber pieces.

Thermally modified timber can be used with both our Trendplank and Satinplank systems. Satinplank is extremely customisable and specifically designed for internal applications and corresponds well with the thermally modified timber that is lightweight and easy to install.

Certain timber species that we offer can provided in different profiles, sizes and finishes. We have tested and with our timber industry experience, found the best combination to result in the best timber product.

Is thermally modified timber BAL rated?

Thermally-modified timber has no BAL rating. Check out more information about timber species and their fire information here.

Finishing and Maintaining thermally modified timber

The finishes applied to internally-installed thermally modified timber are designed to highlight, not hinder the appearance of the timber. Those include Fireshield and Enviro Clear.

For example, Burnt Ash with SiOO:X coating creates and beautiful and consistent silver, grey patina across the the timber pieces. This natural, thermally modified timber also produces a strong crackle and texture in the timber when charred with our Shou Sugi Ban technique.

Is thermal modification the same as kiln drying?

The thermal modification process is different to kiln drying. Kiln drying is used to reduce moisture content in the wood but does not change the wood at a cellular level as the thermal treatment does.

The kiln drying process can help the wood adjust to an indoor or outdoor application with minimal expansion and shrinkage.

Is thermally modified timber sustainable?

While thermally modified timber offers exceptional durability and longevity, its sustainability depends on responsible sourcing practices and efficient manufacturing processes. At Mortlock Timber, we prioritize sustainability by sourcing timber from responsibly managed forests and employing eco-friendly production methods.

At Mortlock, our dedication to sourcing sustainable forest products is more than a commitment—it’s a responsibility. We proudly hold a chain of custody certification for forest products that meet the rigorous standards of AS 4707 and PEFC ST 2002.

Mortlock Timber offers three thermally modified timber species on request, that fall under PEFC Chain of Custody:

- Tulipwood

- Burnt ash

- Vacoa

To our understanding Malvec is under OLB Chain of Custody. However we are unable to substantiate these claims and that is why we have not listed it ourselves under our PEFC certification. This is because while we may be able to attain 40%, 50%, 60% sustainably sourced Malvec/ayous for a particular order, we cannot guarantee the required 70% that is set by the PEFC organisation.

Other timber suppliers do state their FSC and PEFC certification do extend to thermally modified ayous. Though as we are trying to take the correct steps forward in our sustainability journey, we at Mortlock Timber want to be pass onto the client the correct information about the timber we are supplying.

How does thermally modified timber perform in Australia?

The Australian climate can be unpredictable as much as it is predictable. Make sense? Of course not. The dry heat of Western Australia is much different than the heat and humidity found on the eastern coast of Australia.

In our climate(s), thermally modified timber demonstrates remarkable resilience. Unlike traditional wood, the timber maintains its durability and stability even in harsh conditions, making it a preferred choice for architectural projects across the country.

This however is determined by whether the thermally modified timber has been treated or not.

Why choose thermally modified timber

Thermally modified timber cladding can be an affordable option, depending on the scope of the project and the finishes required. We found that Malvec is an amazing alternative to Western red cedar at a more affordable rate. Our Tulipwood is affordable but beautiful for both internal and external options. And Burnt Ash, whether coated in SiOO:X or charred with our Shou Sugi Ban technique. The best way to get an accurate quote for thermally modified wood pricing is to contact us directly. We can work closely with you to find the right solution for your project specifications and budget.

Get in touch today for more information regarding our architectural timber products or to request a quote. One of our friendly team members will be happy to assist you!

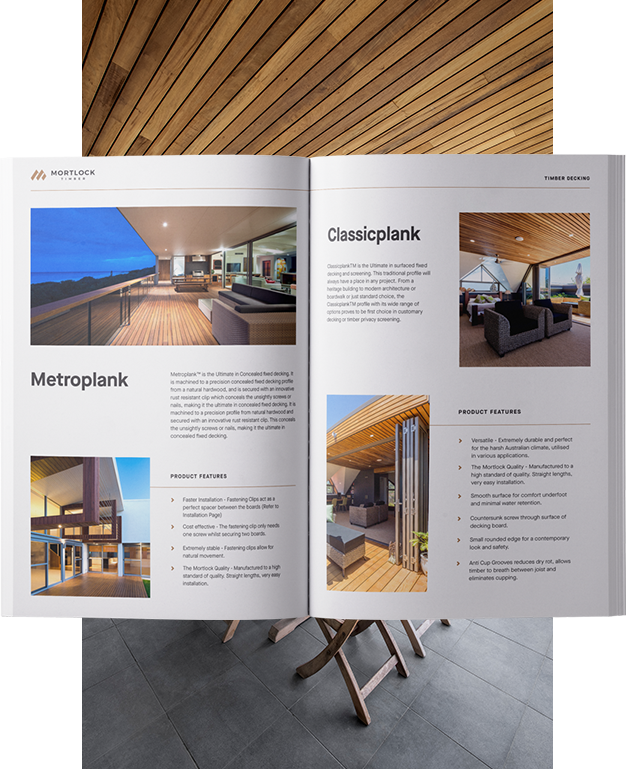

View our pricing and product guide

We are committed to bringing you timber products that add value and endure for years to come, even in heavy traffic and harsh weather conditions. We understand the value of efficiency when it comes to installation and keeping hardwood timber costs down. That’s why we’ve spent decades perfecting our designs to make them easier to handle, less wasteful and more efficient to install. This efficiency allows us to offer you premier products that are more cost-effective so that you can experience greater savings on timber wall costs, timber ceiling costs, timber cladding costs and timber decking costs.

Download our Pricing and Product Guide for our complete hardwood timber price list including timber decking prices, timber wall prices, timber ceiling prices and timber cladding prices.