How to prevent and minimise timber leaching and tannin bleed.

Timber is a beautiful and renewable resource, being grown – not man-made. However, there are specific characteristics you need to consider when building with this natural material. For timber, leaching should be considered when choosing a species.

At Mortlock timber only supply natural timber – and all natural timber have tannins that may cause timber leaching.

In this guide, we will discuss:

- What timber leaching is

- What are tannins

- How to prevent or minimise timber leaching

- How to remove tannin bleeding on surfaces

- Which species we recommend using to avoid timber leaching

What is timber leaching?

Timber leaching is when the wood releases its natural oils and resins when exposed to moisture. This leaching or bleeding primarily happens when timber is exposed to the weather, causing water run-off and when dried, leaves brown and rusty looking bleed marks on other surfaces.

What are tannins?

These brown, black or rusty stains from timber leaching are because of water-soluble extractives called tannins. Tannins are one of the many natural extractives present in timber and released from the timber when wet. However, tannins give timber species their distinctive traits such as their colour, texture and durability.

Tannin is present in all natural timber including bark, stems and leaves. However, the amount of tannin in a particular timber species varies from low to high. See further down for a list of species that we offer and their tannin counts.

Tannin poses no corrosion risk and is solely an aesthetic issue.

What to be aware of when using natural timber on a project.

Consider during the planning and design phase that run off from the timber façade occurs over a garden bed or into an upper story gutter or install suitable flashings are installed to insist in deflecting the water away from a porous surface.

Do not use timber

The only method to 100% avoid timber leaching and tannin stains is to not use natural timber. Composite timber products do not leach as they do not contain any resins in the finished product. So a lot of the issues mentioned above are mitigated. Composite timber comes with its own

A strong solution to leaching, is to use a thermally modified timber.

The best way to prevent leaching is through timber species selection process.

Thermally modified timber is wood that has been heated in temperatures greater than 190°C to create changes in the wood at a cellular level. These structural and chemical changes improve the timber’s durability, stability and resistance to rot and termites.

The little to no moisture in the timbers means that there is no water available to cause swelling, shrinking or warping of the timber that is exposed to the weather – that is ever-changing. This also reduces the number of tannins in the timber, significantly reducing the amount of timber leaching that occurs.

Installing promptly and effectively

Properly installing timber before laying down paving (especially white and grey) is crucial to mitigating the effect of timber leaching. Installing the timber before installing other materials around or beneath the timber, will allow the tannins to bleed and reduce the risk of discolouration and staining.

Additionally, swift installation is essential to prevent the adverse effects of weather and other factors that can affect timber that is sitting on worksites.

Being proactive and ensuring installation is taking place at the specified time in the project timeline, will minimise project-harming situations.

Avoid leaving timber in unfavourable conditions

While storing natural timber, it is important to be aware of the factors that can affect it. While storing timber in cold weather is not necessarily bad, high moisture conditions and extreme temperature conditions will have adverse effect on the timber and the coating applied to it.

An example of this would be timber cladding being delivered to site at the agreed upon and designated time, yet the project has fallen two months behind schedule. The timber cladding is then sitting on site in its pack for an extended period. As the timber is pre-finished, the coating and tannin will build up and sit on the surface of the timber. This occurring during the colder months rather than the warmer months will also have a significant impact on amount of timber leaching. It is important to keep in mind how natural timber interacts with the natural elements and changes, regardless of onsite conditions.

How to remove tannin bleeding on surfaces

Bleeding from timber is temporary and typically occurs during rainy seasons as tannins are expelled. While finishes like oils or tannin blockers can reduce bleeding, most timbers will still release tannins within the first year, even with treatment.

While it is quite difficult to completely remove tannin leaching, there are methods available that will significantly reduce the unsightly stain on surfaces.

Tannin Remover

Tannin removers are products that made readily available at local hardware stores across Australia. Intergrain® UltraPrep™ Tannin & Oil Remover is low VOC product that is designed to lift and remove tannin stains. It is not a paint or varnish stripper and it is recommended to use the appropriate safety and protective gear when applying.

Steps when using Intergrain® UltraPrep™ Tannin & Oil Remover:

- Remove surface dirt by sweeping or washing down with water.

- Shake UltraPrep Tannin & Oil Remover thoroughly.

- Apply UltraPrep Tannin & Oil Remover undiluted with a stiff bristle brush, broom, or spray. Do not use a wire brush.

- Leave UltraPrep Tannin & Oil Remover on the timber for 10–15 minutes. If necessary, apply more UltraPrep Tannin & Oil Remover to keep timber or surfaces damp throughout this period. Do not allow UltraPrep Tannin & Oil Remover to dry on the surface.

- Proceed to scrub then rinse off exterior surfaces thoroughly using maximum pressure from a garden hose or using a high pressure water cleaner. For best results, a high pressure water cleaner is recommended.

IMPORTANT: Failure to thoroughly remove UltraPrep Tannin & Oil Remover may result in timber discolouration under clear finishes. Please refer to the manufacturer website for more information and guidelines.

Removing tannin stains with organic compound

Oxalic acid is a fairly safe dicarboxylic acid that is used for cleaning applications that require a tough approach. To effectively eliminate timber tanning stains from concrete before they fade on their own, you can employ a solution of oxalic acid mixed with warm water.

Apply this mixture onto the stained surface, allowing it to penetrate, and then rinse it away using a hose or pressure washer. If the stains on the surface persist, apply a diluted solution of warm water with baking soda.

To remove these stains, we recommend making up a solution of one part Oxalic acid to ten with water and apply. Keep wet for 10 -20 minutes with solution, scrub with a bristle brush or broom and then wash clean with copious amount of water. Ensure that you are wearing protective clothing and safety glasses.

What are some species that do not leach timber?

All timber species have tannins in them, making then highly susceptible to timber leaching. What we have learned is that the best way to prevent leaching, when wanting to specify natural timber for your project, is through careful timber species selection.

The answer is that in general, white woods have a low tannin content and yellow, red or brown coloured woods tend to contain more tannins. Let’s get into what timber species of ours perform when comes to using them on external applications.

What timber will have tannin problems?

Moderate chance of medium level of tannin leaching. Leeches less than other timbers such as Merbau

Pacific teak

Moderate chance of high level of tannin leaching.

Merbau

Avoid this timber if you are scared of leaching. Mortlock timber does not provide this timber.

Blackbutt

Blackbutt has high chance of leaching with moderate levels of tannins bleeding.

Ironbark

Moderate chance of medium level of tannin leaching. Leeches less than other timbers such as Merbau

Jarrah

High chance of medium level of tannin leaching. Leeches less than other timbers such as Merbau

Western red cedar

Western Red Cedar doesn’t typically stain other surfaces when wet, but it may experience occasional mild extractive bleeding.

How do we take steps to prevent timber leaching affecting materials?

Prevention is always better than cure however to completely eliminate tannin leaching is difficult but it is possible to reduce leaching. Tannin also reduces over time and generally lasts up to 4-5 months depending the level of moisture the timber is exposed to.

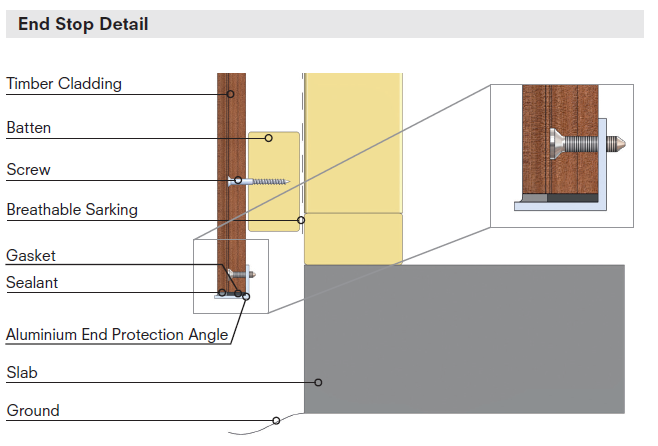

Sealing the end grain of the timber using our proprietary aluminum trims with a sealant to keep tannins in. Below is an example of our Trendplank timber cladding using an aluminium L angle with a foam gasket and sealant (Sealant can be Sika 11FC or similar) to seal the timber end grain.

Let’s avoid timber leaching together!

The team at Mortlock Timber are able offer advice to eliminate concerns relating to timber leaching for your project. Get in touch today for more information regarding our architectural timber products or to request a quote. One of our friendly team members will be happy to assist you!

View our pricing and product guide

We are committed to bringing you timber products that add value and endure for years to come, even in heavy traffic and harsh weather conditions. We understand the value of efficiency when it comes to installation and keeping hardwood timber costs down. That’s why we’ve spent decades perfecting our designs to make them easier to handle, less wasteful and more efficient to install. This efficiency allows us to offer you premier products that are more cost-effective so that you can experience greater savings on timber wall costs, timber ceiling costs, timber cladding costs and timber decking costs.

Download our Pricing and Product Guide for our complete hardwood timber price list including timber decking prices, timber wall prices, timber ceiling prices and timber cladding prices.