How to prevent and minimise timber leaching and tannin bleed.

Key take aways

Timber is natural, renewable material, and like all natural products, it contains extractives that respond to environmental exposure. Most timber species contain tannins, which may leach when the timber is exposed to moisture.

While tannin leaching can occur across almost all timber species, the likelihood and severity vary depending on the species, site conditions, and exposure to the elements.

This guide outlines what tannin leaching is, why it occurs, and the practical steps that can be taken to mitigate its effects.

In this guide, we will discuss:

- What is Timber Leaching?

- What are Tannins?

- How to prevent or minimise timber leaching

- How to remove tannin staining on surfaces

- Which species we recommend using to avoid timber leaching

What is timber leaching?

Timber leaching is the release of natural oils, resins and extractives when the wood is exposed to moisture. This leaching or bleeding primarily happens when timber is exposed to the weather, causing water run-off which, when dried, leaves brown or rust-coloured bleed marks on other surfaces.

What are tannins?

Stains from timber leaching are caused by water-soluble extractives called tannins. Tannins are a natural component of all timber species and are most commonly leached when the timber is exposed to moisture. While tannins can cause temporary staining, they also contribute to a timber’s natural colour, texture and durability.

Tannins are present in all natural timber, however, the amount of tannin in a particular timber species varies. Tannin stains are water soluble and pose no corrosion risk. Tannin stains are purely an aesthetic issue that can be managed with light maintenance practices and cleaning.

How do I avoid tannin leaching in my project?

When planning your project, it’s important to think about where rainwater will run off from timber surfaces and where that water will go. With the right planning and detailing in place, tannin leaching can be managed effectively. The following sections outline the practical options available to help minimise staining and reduce its visual impact over time.

Do not use timber

The only way to completely avoid tannin leaching is to not use natural timber. Because tannins are a naturally occurring component of wood, any natural timber has the potential to leach when exposed to moisture. Alternative products such as composite or synthetic materials do not contain natural extractives and do not experience tannin leaching. Natural timber is often chosen for its character and sustainability for many projects and with good planning, species specification and detailing, tannin leaching can usually be managed and minimised rather than eliminated.

Use Thermally modified timber.

The best way to prevent leaching is through timber species selection process. Thermally modified timber is timber that has been heated to temperatures above than 190°C in a controlled, low-oxygen environment, creating permanent changes at a cellular level.

This process improves the timber’s durability, dimensional stability and resistance to rot and termites. Importantly, thermal modification removes resins and significantly alters the extractives within the wood, meaning thermally modified timber has a reduced risk of tannin leaching.

Because the timber absorbs far less moisture than untreated wood, it is less prone to swelling, shrinking or warping when exposed to changing weather conditions. As a result, thermally modified timber performes reliably in external applications while greatly reducing the likelihood of tannin staining.

Installing promptly and effectively

Properly installing timber before adjacent materials such as paving (particularly light-coloured finishes like white or grey) is an effective way to help manage timber leaching.

Timely installation is also important to limit prolonged exposure to weather and site conditions. Ensuring timber is installed in line with the project schedule helps minimise delays, handling issues and avoidable on-site complications.

Avoid leaving timber in unfavourable conditions

While storing natural timber, it is important to be aware of the factors that can affect it. While storing timber in cold weather is not necessarily bad, high moisture conditions and extreme temperature conditions will have adverse effect on the timber and the coating applied to it.

For example, if timber cladding is delivered to site but the project is delayed, the timber may remain stored site for extended periods. During this time, tannins and coating residues can build up on the surface, particularly during colder months, increasing the likelihood of leaching once installed.

How Penetrative Oil Finishes Interact with Tannins

Penetrating oil finishes are commonly used on external timber as they allow the timber to breath and move naturally with changes in moisture and temperature. As a result, tannin leaching may still occur during early exposure to moisture, particuarly when timber is newly installed or subject to frequent wetting. This behaviour is normal and does not indicate a failure of the coating.

CUTEK Wood Oils are deeply penetrative and non-film forming, meaning they protect timber from within rather than creating a surface coating. As a result, timber treated with CUTEK oils remain breathable.

Over time, as natural extractives are flushed from the timber, visible tannin leaching will reduce. CUTEK oils are designed to work with this natural process while providing long-term protection to the timber.

Removing Tannin Stains

Tannin staining caused by leaching is generally a temporary issue and will reduce over time as the timber weathers. Where staining does occur on the timber itself or on surrounding surfaces, it can usually be managed with appropriate cleaning methods.

When working with timber finished using a penetrating oil system, Mortlock Timber recommends cleaning products that are compatible with breathable coatings and natural timber substrates.

For detailed technical information, including data sheets an safety documentation, refer to https://www.cutek.com.au or speak with the Mortlock Timber team.

Using CUTEK QuickClean

CUTEK QuickClean is designed to remove surface contamination and help flush extractives, including tannins from timber. It is particularly useful where timber has been exposed to wet conditions prior to coating, or where early-stage tannin bleed is visible.

QuickClean is commonly used as a preparatory step before applying a CUTEK oil finish, helping to remove surface build-up and reduce the likelihood of ongoing staining. It may also be used to clean light staining where leaching has already occurred.

Using CUTEK Restore

For more noticeable staining or discolouration, CUTEK Restore can be used to life tannins and other extractives from the timber surface and restore a more even appearance. It’s suited to situations where staining has become more pronounced or where timber has weathered unevenly.

CUTEK Restore may also be used to assist in cleaning tannin staining on adjacent surfaces such as concrete or masonry. Care should be taken to protect surrounding materials, and a small test area should also be completed before treating larger surfaces.

Step 1: Cleaning with CUTEK QuickClean

- Ensure the timber surface is dry and free from debris.

- Dilute CUTEK QuickClean with water in a 3:1 ratio (three parts water to one part QuickClean).

- Apply the solution evenly to the timber surface using a brush, broom or applicator.

- Keen the surface wet and work in manageable sections to prevent the solution from drying out.

- Scrub the timber using a deck scrubbing brush or soft-bristled broom.

- Rinse thoroughly using a pressure washer with fan-pattern nozzle, working slowly along each board to ensure all residues are removed.

Approximate coverage is 4-7 square meters per litre when diluted.

Step 2: Treating Staining with CUTEK Restore

- Pre-wet the timber surfaces with clean water prior to application.

- Apply undiluted CUTEK Restore liberally using. brush, roller or lambswool applicator, ensuring affected areas are fully covered.

- Allow the product to remain on the surface until the timber lightens to a satisfactory and even appearance. For heavier staining, Restore may be left on the surface for an extended period.

- Once the desired result is achieved, rinse thoroughly using a pressure washer fitted with a fan-pattern nozzle, working evenly along each board to remove all residue.

Approximate coverage is 5-8 square meters per litre when diluted.

Pressure Washing Technique

When rinsing CUTEK QuckClean products from the timber surface, use a pressure washer fitted with a fan-pattern nozzle to ensure even coverage. Move the spray slow and methodically along each board, passing over the surface at least once to fully remove cleaning residues. Pressure should be kept at a moderate level (around 750 psi), with a fan width of approximately 100mm at the timer surface.

Additional application and cleaning guidance is available via the manufacture’s video resources. https://www.youtube.com/@cutek-effectivewoodprotect2466

Removing tannin stains with organic compound

Oxalic acid is a fairly safe dicarboxylic acid that is used for cleaning applications that require a tough approach. To effectively eliminate timber tanning stains from concrete before they fade on their own, you can employ a solution of oxalic acid mixed with warm water.

Apply this mixture onto the stained surface, allowing it to penetrate, and then rinse it away using a hose or pressure washer. If the stains on the surface persist, apply a diluted solution of warm water with baking soda.

To remove these stains, we recommend making up a solution of one part Oxalic acid to ten with water and apply. Keep wet for 10 -20 minutes with solution, scrub with a bristle brush or broom and then wash clean with copious amount of water. Ensure that you are wearing protective clothing and safety glasses.

What are some species that do not leach timber?

All timber species have tannins in them, making then highly susceptible to timber leaching. What we have learned is that the best way to prevent leaching, when wanting to specify natural timber for your project, is through careful timber species selection.

The answer is that in general, white woods have a low tannin content and yellow, red or brown coloured woods tend to contain more tannins. Let’s get into what timber species of ours perform when comes to using them on external applications.

Timber Species and Relative Tannin Leaching Risk.

All natural timber contains tannins, however the likelihood and severity of visible tannin leaching varies by species. The following grouping provides a general guide to relative leaching risk when timbers are used in external applications.

High Leaching Risk

More likely to produce visible tannin staining, particularly during early exposure to moisture.

- BlackButt

High likelihood of leaching, with moderate to high levels of tannin bleed.

- Jarrah

Higher likelihood of leaching, with moderate levels of tannin bleed. Typically leaches less than vary high-tannin species such as Merbau.

- Pacific Teak

Moderate to high likelihood of tannin leaching, particularly in wet or exposed conditions.

Moderate Leaching Risk

May exhibit tannin leaching under certain conditions, generally less sever than high-risk species.

- Spotted Gum

Moderate likelihood of medium-level tannin leaching. Generally leaches less than very high-tannin species such as Merbau.

- Ironbark

Moderate likelihood of medium-level tannin leaching. Typically lower risk than high-tannin species.

Lower Leaching Risk

Less likely to cause visible staining, through minor extractive bleed may still occur.

- Western Red Cedar

Generally low risk of staining adjacent surfaces when wet, though occasional mild extractive bleeding may occur.

Very High Leaching Risk (Not Supplied by Mortlock Timber)

Known for significant tannin leaching.

- Merbau

Very high tannin content and a high likelihood of leaching. Mortlock Timber does not supply this species.

Bundanoon, NSW – Thermally-modified timber – Vacoa stained in WOCA Black Exterior Oil.

How do we take steps to prevent timber leaching affecting materials?

Prevention is always better than cure however to completely eliminate tannin leaching is difficult but it is possible. Over time, timber naturally reduces the amount of leaching as the tannins within the timber disperse. Tannin leaching would generally last up to 4-5 months depending the level of moisture the timber is exposed to and the timbers species.

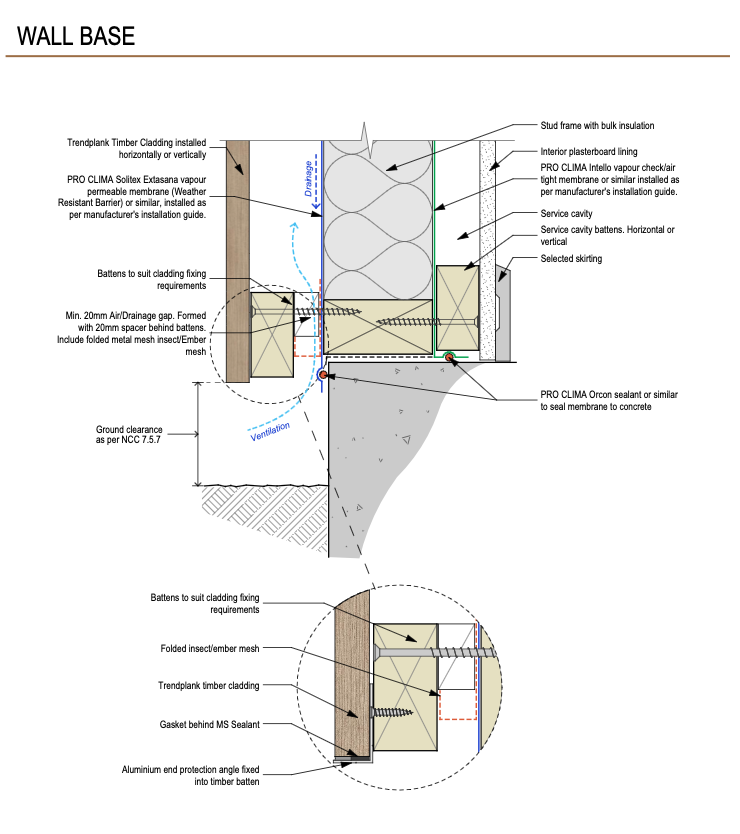

Using a physical barrier to seal the end grain of the timber using our proprietary aluminium trims with a sealant is an effective measure to keep tannins in. Below is an example of our Trendplank timber cladding using an aluminium ‘L’ angle with a foam gasket and sealant (Sealant can be Sika 11FC or similar) to seal the timber end grain.

Let’s avoid timber leaching together!

The team at Mortlock Timber are able offer advice to eliminate concerns relating to timber leaching for your project. Get in touch today for more information regarding our architectural timber products or to request a quote. One of our friendly team members will be happy to assist you!

View our pricing and product guide

We are committed to bringing you timber products that add value and endure for years to come, even in heavy traffic and harsh weather conditions. We understand the value of efficiency when it comes to installation and keeping hardwood timber costs down. That’s why we’ve spent decades perfecting our designs to make them easier to handle, less wasteful and more efficient to install. This efficiency allows us to offer you premier products that are more cost-effective so that you can experience greater savings on timber wall costs, timber ceiling costs, timber cladding costs and timber decking costs.

Download our Pricing and Product Guide for our complete hardwood timber price list including timber decking prices, timber wall prices, timber ceiling prices and timber cladding prices.